Lever 1: KappaQ-Energy Design

The first lever ‘Design’ describes the influence of the solution design on the energy efficiency of the entire ventilation system.

The use of energy to operate exhaust air, process air or ventilation systems cannot be avoided. However, it is possible to reduce the amount of energy required. Energy-efficient system planning forms the basis for this. Our experience shows that inadequate consideration of energy efficiency in the solution finding and system planning phase can no longer be compensated for. It is therefore all the more important to consider energy consumption as early as the planning phase.

Once the optimum ventilation and air conditioning solution has been determined, the correct design and dimensioning is crucial for optimum energy efficiency. Incorrect dimensioning leads to malfunctions because too little air is conveyed. The result is an undersupply due to insufficient capacity. In the case of oversizing, incorrect planning leads to oversupply. In the first case, the system is not functional and in the second case, an unnecessary amount of energy is consumed.

OUR RECOMMENDATION

- Use the experience in your company. Draw on the expertise and solution concepts of external partners when planning.

- Dimension your ventilation and air conditioning system to the point. Here too, it is advisable to make use of the expertise of external partners.

- Always assess individual solution concepts holistically. This means that, in addition to the basic function, you should always take the expected energy consumption into account. To do this, draw up a list of the current energy requirements and compare this with the investment costs.

Case study

Energy-efficient overall view

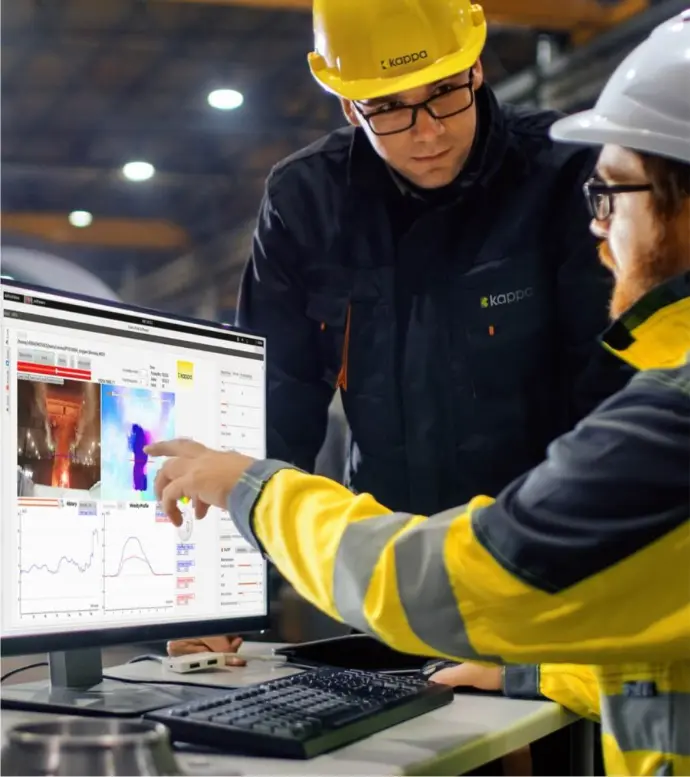

Our customer asked us to plan a process exhaust air system for capturing and extracting emissions from their hardening bath. Various solutions had already been proposed for this requirement. The design and dimensioning of the proposed solutions were based on the experience of our customer and the suppliers involved. During the initial inspection, we realised that the quantity and the surge-like spread of the emission clouds made experience-based dimensioning impossible. For this reason, our first step was to try to determine the emission characteristics and quantity. However, there were no suitable analysis tools for this.

That is why we developed the Kappa Video-Fluid-Dynamic (VFD) software. It is based on video recordings that can be used to determine the speed, extent and quantities of visible emissions. With the results obtained, the required capture and extraction could now be correctly determined.

RESULTS

- The Kappa VFD analysis of the mass flows enabled the capture to be optimised. This led to a 34% reduction in the required extraction volume flow (compared to the existing design and compared to dimensioning in accordance with VDI standards).

- The electricity consumption required to operate the ventilation technology was reduced by 334,850 kWh per year. This corresponds to an energy saving of 53%.

- This saves 245,100 kilograms of CO2 every year. This corresponds to the amount of CO2 that 19,600 mature beech trees emit each year.

More ABOUT

the kappa vfd analysis method

KAPPAQ-ENERGY DESIGN

IS A LEVER OF THE

ENERGY-EFFICIENCY-CONCEPT

»KAPPAQ-ENERGY«

Kappa-Q-Energy is the energy-saving concept for minimising the energy costs of ventilation systems.

It illustrates which factors influence the energy requirements of ventilation and air conditioning systems and which levers make it possible to massively reduce energy consumption in the long term.