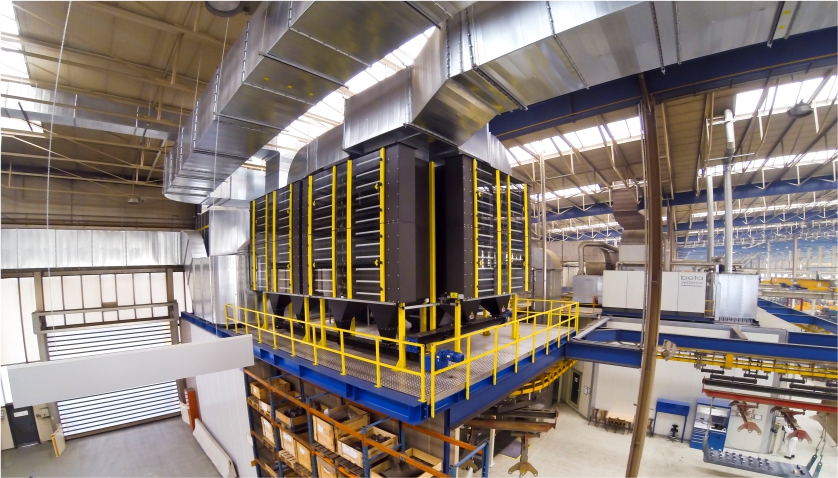

Innovative hall air purification system at Liebherr-Werk Telfs for low pollution levels at the workplace and optimum energy efficiency.

Tyrol is proud of its nature, its mountains, its fresh air and Tyrol is proud of its products, which are used and appreciated all over the world. Just like Liebherr, which is the only plant in the Group to manufacture loaders and bulldozers, pipe layers and telescopic handlers in Telfs. In addition to state-of-the-art production technologies, the company also attaches great importance to occupational safety and environmental protection. In 2014, a new, innovative hall air purification system was installed in the steel construction area. In addition to efficient hall air purification in steel construction, Kappa was also able to save energy and heating costs. "With this investment, we are demonstrating that the safety and protection of our employees is extremely important to our company. It is also a clear commitment to the production site in Telfs," reports Alexander Katrycz, Head of Marketing at Liebherr-Werk Telfs GmbH.

Active reduction of pollution in the workplace

The innovative hall air purification system not only ensures clean air and minimal pollution, but also reduces energy costs. Kappa has succeeded in “squaring the circle” by intelligently combining exhaust air and ventilation technology in one system. The emissions are captured over the entire area of the steel construction and Kappa Mykron® fine dust filter separates these highly effectively. This technology enables a significantly better separation performance of fine and ultra-fine dusts compared to conventional systems - dusts that can penetrate into the alveoli of the respiratory organs are captured, making environmental protection an occupational health and safety issue.

A total of 140,000m³/h of exhaust air is purified to a high degree. Due to the excellent separation performance of the filter system, the waste heat is recovered with a high degree of efficiency and the production hall can be heated largely without additional energy. The heat recovery system has an output of 1100 kW.

Well below the legally prescribed value

Kappa's supply air system ensures an even supply of fresh air. The clean air is introduced into the work area, free of pollutants, at a pleasant temperature and completely without draughts or turbulence. The workplace concentration of dust is below the agreed 1 mg/m³ and therefore well below the legally prescribed value.

"The air quality in the welding shop is now very good thanks to our new hall air purification system. Despite the low outside temperatures in winter, we hardly had to add any heat. Before, we lost the waste heat through the roof, now we can use it. “Johann Struc, Head of Work Organization at Liebherr-Werk Telfs.”

As flexible as production

„Das Kappa Airdynamic System "The Kappa Airdynamic system permanently monitors the emission load in production and adjusts the air purification system throughout the entire hall accordingly. The system works completely automatically and reliably," explains Karl Rieger, Technical Manager at Kappa. If more is produced, i.e. more emissions are generated, the system reacts immediately by increasing its output. If the machines are not working at full capacity, the output of the ventilation system is reduced fully automatically. Thanks to the intelligent system control, 265,000 kWh of electricity can be saved each year.

Task overfulfilled

The adaptation to actual requirements, the recovery of waste heat and the fullfilling of the specifications required by the customer represent a new milestone. “The hall air purification system we planned and implemented on a turnkey basis thus ensures optimum reduction of pollutants in the workplace and also sets new standards in terms of energy efficiency,” says Harald Schneuber, Project Manager at Kappa.