Energy retrofit: retrofitting exhaust air and ventilation systems in an energy-efficient way.

When it comes to the digitalization of systems and the optimization of energy consumption, the integration of existing systems is often a challenge. While digitalization and energy monitoring are increasingly being considered in the system and automation architecture when planning new systems, existing systems lack two important prerequisites: the hardware in the form of sensors to record the required data and the control and automation options.

We have therefore developed the “Energy Retrofit” digitalization package.

This is a modular system for your existing ventilation systems that serves four central energy efficiency levers:

- Components - Energy Retrofit can be used to identify the central, energy-consuming components.

- Discovery - Energy Retrofit can be used to identify energy resources that can be utilized.

- Service – Energy Retrofit can be used to plan and implement the service based on energy-related parameters.

- Redesign – Energy Retrofit lays the foundation for ongoing energy optimization of your systems.

With these four levers, Energy Retrofit makes it possible to “make fit” and, above all, to “keep fit” existing ventilation systems.

The possible applications for digital retrofitting are wide-ranging and solutions are being sought across the board in the industry. A sensor-communication retrofit requires an application-related inventory and feasibility analysis. To minimize the effort involved, Energy Retrofit consistently relies on standardization::

- Standardized air technology sensors: Energy Retrofit relies on high-quality sensors in industrial design. They determine parameters relevant to ventilation technology, such as differential pressure sensors, which provide information about the filter status. Other sensors include temperature sensors and volume flow sensors.

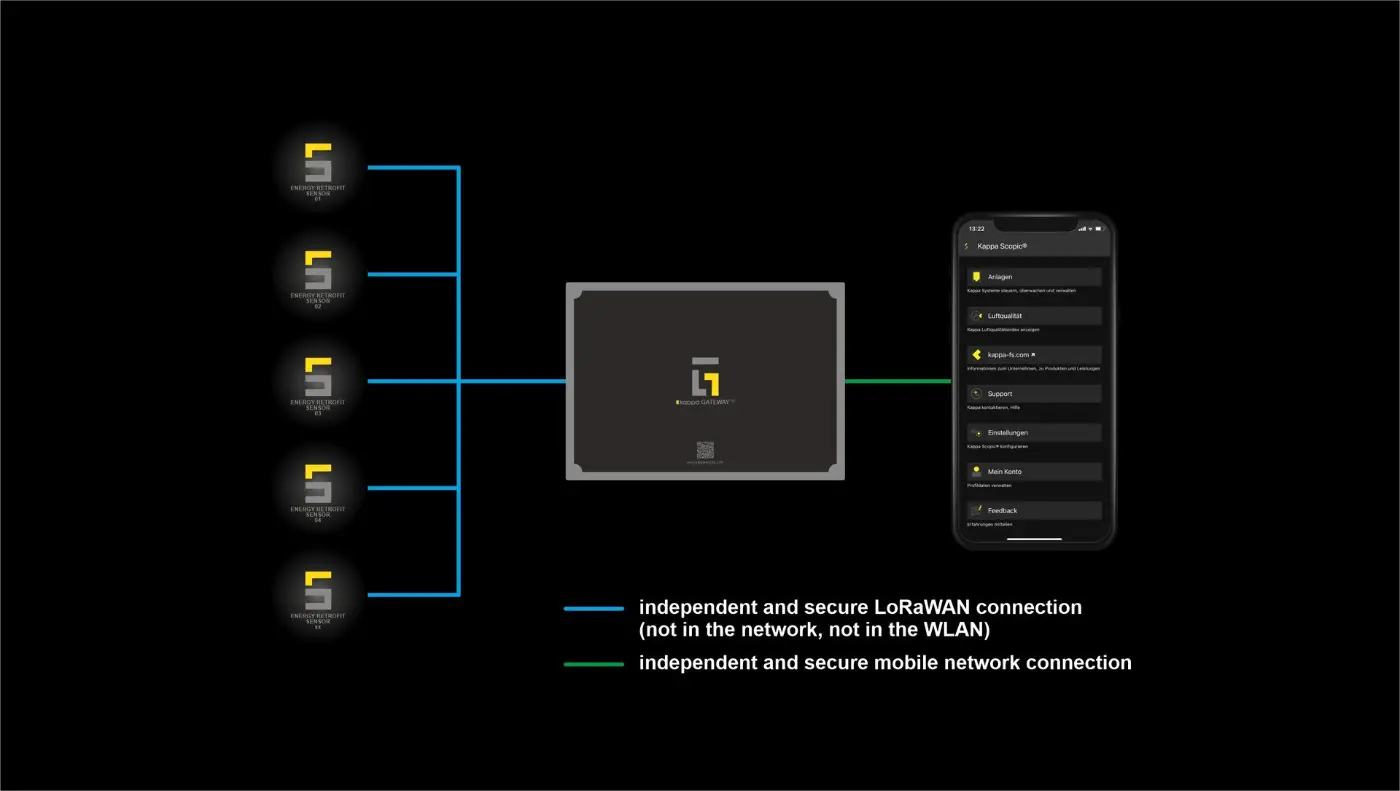

- Standardized data collection and processing: Energy Retrofit collects and compresses the data collected.

- Standardized data provision: Energy Retrofit makes the collected data available in the device-independent Kappa Scopic® software. It enables you to access your Energy Retrofit data via PC, tablet or cell phone, no matter where you are.

USE CASES

In the most recently implemented projects alone, the cost-effectiveness of existing systems was significantly increased through “energy retrofits”. The main aim here was to equip existing systems with sensor and control technology during operation. In this way, the required performance and energy data of the system can be collected. The data provided by the air technology can then be used by the system operator to save energy costs: in one case, the energy costs of the existing system were significantly reduced by replacing dirty filter elements. Previously, filter elements were only replaced when they were worn out. The measure has already paid for itself in a short time. This example of a service lever from Energy-Retrofits describes precisely this problem: filter elements that are already heavily clogged consume an above-average amount of energy. Replacing them in good time results in significantly lower energy costs. In another system, an ageing fan was identified as an excessive energy consumer and replaced. The components lever of energy retrofits thus led to significantly reduced electricity costs. Both levers are examples of the effectiveness of Energy Retrofit and show that energy can be saved sustainably.